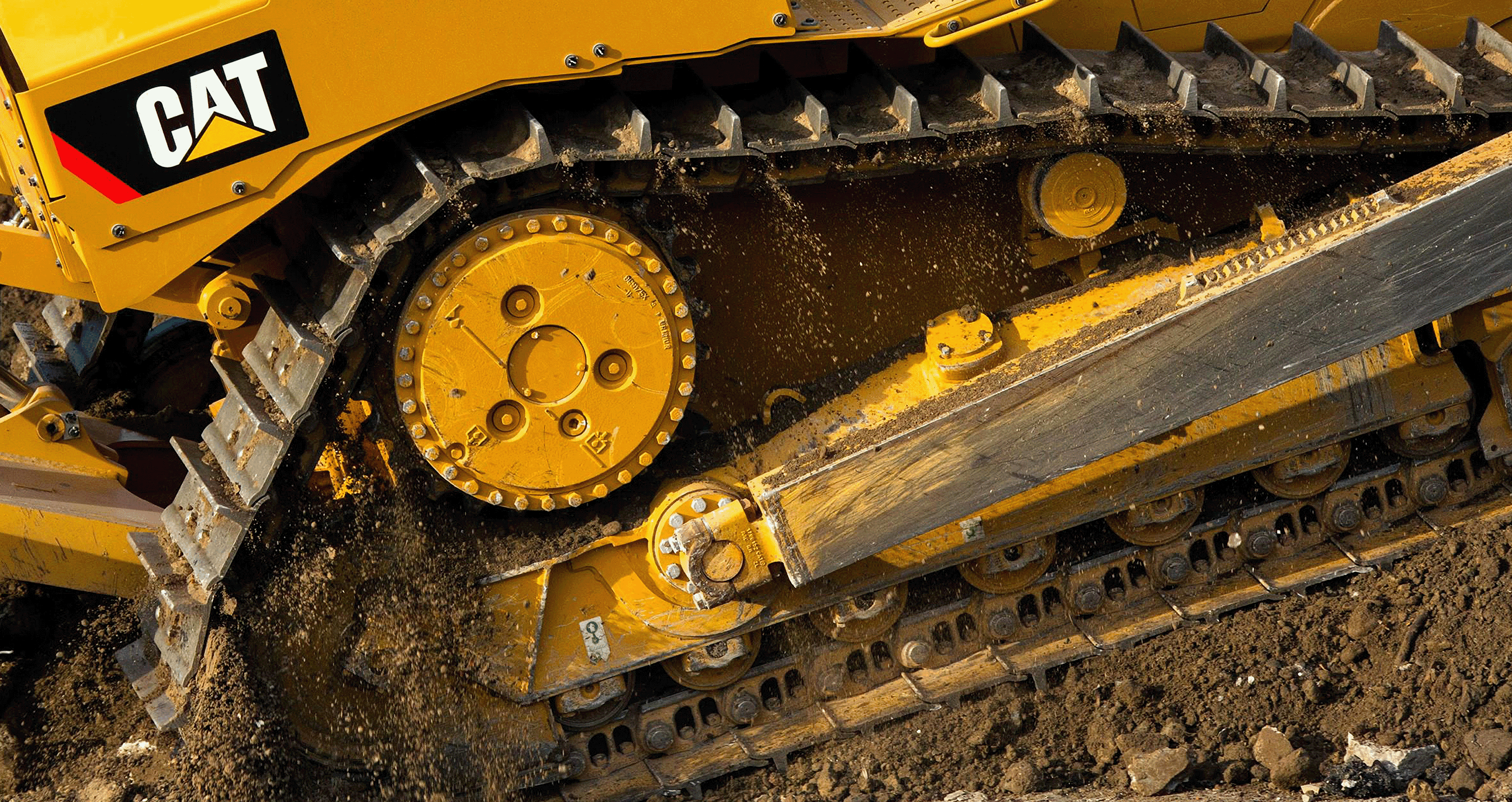

With a legendary Cat® pedigree, the 150 motor grader offers peak performance, efficiency, long life and operator comfort. Available with a deep array of technologies to lessen the load on operators and enhance grading performance, the motor grader is one highly productive machine.

Motor Graders

24/7 Customer Support

Questions? We're here to help.

Learn MoreGenuine Cat Parts

Extend the life of your equipment with Genuine Cat Parts and Service.

Learn MoreService Agreements

Maximise uptime. Improve productivity. Reduce costs.

Learn MoreOverview

Reduce your carbon footprint with the latest in emissions reduction technology with the durable Cat® 150 Motor Grader. The 150 motor grader unites comfortability and productivity to get optimal performance on the jobsite. Get the best visibility with angled cab doors, tapered engine enclosure, and sloped rear window.

- Net Power Range (Tier 4)149kW

- Bore115mm

- Stroke149mm

- VHP Plus - Gear - Net Power - Reverse 1st149kW

- VHP Plus - Gear - Net Power - Forward 1st149kW

- Maximum Torque - VHP Plus1247N·m

- VHP Plus - Gear - Net Power - Forward 8th188kW

- VHP Plus - Gear - Net Power - Forward 6th180kW

- VHP Plus - Gear - Net Power - Forward 2nd156kW

- VHP Plus - Gear - Net Power - Forward 7th184kW

- VHP Plus - Gear - Net Power - Forward 5th176kW

- Standard Capability43°C

- VHP Plus - Gear - Net Power - Reverse 3rd-6th164kW

- VHP Plus - Gear - Net Power - Forward 4th172kW

- Base Power (1st Gear) - Net - Metric149kW

- VHP Plus - Gear - Net Power - Reverse 2nd156kW

- VHP Plus - Gear - Net Power - Forward 3rd164kW

- Displacement9.3l

- Derating Altitude3050m

- High - Ambient Capability50°C

Overview

DESIGNED FOR OPERATORS

<ul><li>Good visibility is key to safety and efficiency. Angled cab doors, tapered engine enclosure and a sloped rear window make it easy to see the moldboard and tires, as well as behind the machine. Optional rear vision camera further enhances lines of sight all around the machine.</li><li>Experience the most spacious, comfortable cab in the industry.</li><li>Easy-to-learn joystick controls replace levers, so hand and arm movement is reduced by 78%, helping reduce operator fatigue for better productivity.</li><li>Left joystick controls steering, articulation, return-to-center, wheel lean, gear selection, left moldboard lift cylinder and float.</li><li>Right joystick controls drawbar, circle and moldboard functions as well as electronic throttle control and manual differential lock/unlock.</li><li>Joystick lean angle mirrors the steer tires' turning angle.</li><li>A brake tensioning system holds the joystick in position until the operator moves it.</li><li>Steering control automatically reduces sensitivity at higher ground speeds for predictable control.</li><li>Infinitely variable roller switches control the rear ripper and/or front lift group (when equipped).</li><li>Control switches are in easy reach.</li><li>Updated seat offers softer cushions, three-position tilt and optional heated and heated/cooled cushions.</li><li>Control pods are electronically positioned allowing each operator to set the ideal operating position.</li><li>Multiple isolation mounts reduce sound and vibration for a more relaxed work environment.</li><li>High capacity Heating, Ventilation and Air Conditioning (HVAC) system dehumidifies and pressurizes the cab, circulates fresh air, seals out dust and keeps windows clear.</li><li>An optional deluxe radio with CD features MP3 and Bluetooth® technology.</li><li>New Message Display shows machine performance and diagnostic information. Located in center console, it also displays Grade Control Cross Slope readings.</li><li>Electronic Throttle Control helps improve productivity by providing the best match of horsepower and torque for the demands of the application.</li><li>Articulation Return-to-Center automatically returns the machine to a straight frame position from any angle with the touch of a button.</li><li>Select Fine, Normal or Coarse blade lift modulation to best fit application or operator preference.</li></ul>

Support

POWER ON THE GROUND